It looks like you've lifted the tracks on all but a couple of the pads. All is not lost, but you will need:

- A soldering iron with a 1mm or finer bit

- Some fine solder - 22SWG or finer

- Solder braid

- Flux pen

- Some thin wire, e.g. a few single strands from some stranded wire.

First of all, clean up the pads. Put some flux from the flux pen on the braid, then press the braid down onto the soldered pads with the soldering iron. (A standard bit is better for this.) The braid will soak up all excess solder.

You only have 2 good pads (3 at a pinch) to solder the replacement chip to. (You did note which way round the original was, didn't you?)

Position the new chip on the pads, and get someone to gently hold it down with a small screwdriver. Or you may be able to hold it down with a sliver of double-sided tape. Apply flux to the pins you're going to solder. Apply the iron (fine tip) to one of the pins and after a second or two, feed in a little solder. Not too much or it'll bridge to the next pin. (You can put that right with the braid.) Hold the iron like a pencil, close to the element and rest your wrist on the bench, so as to get the finest possible control. If your youth is receding you may find a cheap pair of readyspecs of 1 - 2 dioptres will allow you to work much closer.

Repeat with the other surviving pad, and if possible, the 3rd. You may just be able to solder one of the pins on the other side to the remnants of the track.

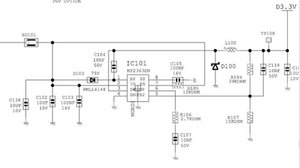

For the other pins, you'll need to connect them with the fine wire. The trashed track from the remaining pin on the bottom clearly goes to R105. Solder one end of a piece of wire to the pin and the other end to the solder end of R105, or else gently scrape the green solder resist off the track and solder direct to that. (Always use flux.)

I can't quite see from the photo where the tracks from the pins on the other side were meant to go but hopefully you can with a good light and a magnifying glass.

Once you've got all the pins connected, check for solder bridges with a magnifying glass and very gently pull each of the wires to make sure its secure. Now test to see if it works. If it does, the new chip will need holding in place with something like hot melt glue.

Good luck!

4

4  2

2

72

72