Ribbon doesn't move when printing

I push the 'print' button' and , although it make some sound, and one of the wheels is turning (the one on the middle bottom) the ribbon doesn't move.

How to fix it?

Es esta una buena pregunta?

I push the 'print' button' and , although it make some sound, and one of the wheels is turning (the one on the middle bottom) the ribbon doesn't move.

How to fix it?

Es esta una buena pregunta?

Ok guys I tried factory resetting, turning the spindle clockwise 5 times, pulling the tape up so it sticks out from the cartridge, and maybe a few other things I forgot. None of that worked, but every time I pressed the little white button on the right I could hear the motor.

Fortunately I have another one of the same model that fell down the stairs. I'd been meaning to take it apart to troubleshoot so I figured what the heck.

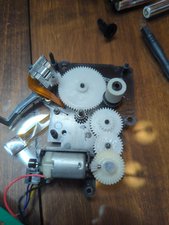

No kidding, I disassembled the thing and learned that there are 8 gears that make this baby go. If one of the gears moves too far up its shaft, it doesn't lock with the other gears and the tape won't move. No less than FIVE of these gears have no stopper to prevent them from slipping up on their shafts. (Yes, 63% of these shafts... How did this pass a design review?!)

So rather than try disassembling the one that still turned on, I tried tapping it a couple times on the back (where the panels are that open up to the batteries and cartridge). This didn't work at first, but I was pretty dang sure this was the problem. So i took my cartridge out and gave the entire label maker several nice firm taps by banging it on my knee.

Wouldn't ya know that freaking worked, 🤣. I guess sometimes our problems can still be simple mechanics.

So... If you've tried everything else and are at your wits' end, try rapping the label maker against the table face down a couple of times. You probably want to put a towel or something down so you don't crack your screen.

*Note- you want to tap it with the face down because the shafts face downward, towards the place where you load the cartridge. This blows my mind even further, because we use this device with the screen facing us, so those gears are in constant danger of slipping up/down on their shafts.

LOL this whole post makes me feel uncomfortable for several reasons. 🤣🤣🤣

Cheers!

Fue útil esta respuesta?

You are a genius!

This, hilariously, worked. Thanks much.

One more vote for the good solid smack

Just want to let you know that your post is a random act of kindness! I'm so glad I stumbled upon this!!! Tapping worked like a charm!!!!

there is a saying....if you can't repair it with a hammer, it cannot be repaired ;-)

smashed it face down on the palm of my left hand (I am righthanded) ... SOLVED (for the time beeing)

Hello, sorry for my bad language (i´m from Italy) but i had the same issue with my device, and i found out, that there is a small spring connecting the lid to a lever inside. Witch pushes the printhead to the tape when you close the lid.

So, if the hole in the lever, where the spring is hooked into, is damaged it can´t work anymore. I fixed this issue by carefully carving out a small piece of the plastic casing to get access to the lever and the spring. Then i was able to reattach both together with a pinzette. If the hole is too damaged for reattachment i suggest it would also be okay to drill a small new whole into the plastic lever, as close as possible to where the original one was.

I also made a picture and uploaded it here:

https://s19.directupload.net/images/2001...

I have no cloud account, so i don´t know a better place to upload it; If someone does and finds this picture useful, please reupload it there!

Fue útil esta respuesta?

All of a sudden my tape was not moving. My spring had cut through the lever and was disconnected on that end. I squeezed the lever in to close the hole a little and then put some real good superglue on it and then screwed the spring loop to the lever with a screw through the original hole. The spring should apply enough tension on the lever.

After getting the spring mounted it must have lost some tension because the tape still wouldn't move so I glued some plastic as a shim behind the printing head so it applied more pressure to the roller. It has been working fine since I added the shim.

This is exactly what had happened to mine. Reattaching the spring and it works perfectly again

Thanks for this!

That was my issue as well, though in my case, the spring had cut through the plastic lever it was connected to.

So I had to cut out some of the cover as described here, patch up the lever with super-glue and some scrap plastic, and thread the spring back in (I had to bend the end a bit to make it fit). Seems to be working now, though I’m concerned that the spring might slip off again. Easy fix now that the back is cut out.

This was my issue as well! The spring broke through the plastic. It's not an easy job, but I managed to open the spring up a bit and get it back together.

Your cartridge door should have a little pull to it. If it doesn't not, your spring is off. Good luck!

On mine, there was some black ink ribbon stuck around the top roller that pulls the ribbon out. Got it out with the small pair of tweezers and the roller was able to grip the ribbon again. Simple fix.

Fue útil esta respuesta?

Will never buy Dymo again. Doesn’t work.

Thank you, this worked for me!

One probably obvious thing I that took me too long to realise was I needed to close the lid after cleaning the top roller, otherwise the roller won’t grip even when cleaned.

Thanks again!

Thank you!!! I was going crazy until I saw this post!!

Thank you! Thank you! my label maker now works! 👍👍

Had same problem with first tape cartridge I installed, which is the same one that came with my Dymo model 160. I removed the cartridge, got out my magnifying glass, and, looking at the side of the cartridge you see when it is installed in the DYMO, found the spot at which the white tape is supposed to separate from the printer cartridge ribbon. This point is about 1/2 inch below the letter “D” in the brand name DYMO on the cartridge. There was already about 1/4 inch white tape sticking out from the point where the black printer ribbon heads back into the cartridge. I managed to grab this small length of white tape and pull it out about 2 inches while preventing the black printer ribbon from moving at all. You can prevent the black tape from moving by using something that fits in the hole, like a pencil eraser, to keep the ribbon spool from moving. The ribbon spool hole is located about 1/2 inch above and to the right of the “O” in the work DYMO. I then cut off all but a quarter inch of the white tape, reinstalled the cartridge, and now have a working Dymo. Good luck. This worked for me.

Fue útil esta respuesta?

This also worked for me. Used some needlenose a pliers to pull the white label just long enough that I could hold it once I closed the back, and just gave it a nudge when I started the first print. All fixed up and no further pressure needed.

I both cleaned the drive roller of my LabelManager 220P (cotton swab and rubbing alcohol) and gave the white tape a bit of a tug -- maybe half an inch rather than 2 inches -- without bothering to do anything special about the color ribbon. Mirabile dictu, it worked. First print was incomplete, but second came out perfectly.

I'm suspecting that I may have gotten fingerprint oils or something like that on the back of the white tape and/or the roller, causing the two to slide rather than advance properly. Either that, or the white tape was slightly out of position when installed and the pull released it. Either way, I'm back in operation.

(I acquired this labelwriter because it hadn't been working well for someone else. Up until today it had worked fine for me... I wonder if they ran into the same problem.)

There are arrows on the wheels that turn to choose the letter to print. It looks like one wheel, but it’s actually 2, a top and a bottom. Two arrows are on the side of the wheel by the scissor icon (top wheel). If you spin the bottom wheel separately, you’ll see another two arrows on it. Line the two sets of arrows up, and it will work again. You might have to work at getting the “ribbon” to feed, but once you get it to, you’re back in business.

Fue útil esta respuesta?

I fixed this easily. I removed the 8 screws from the back. Do this carefully using a small phillips head screwdriver. Take the back of the device off carefully. There is a spring with a hook on the end that hooks over a little black arm. When I took the back off the spring was just loose on one end. I hooked the spring over the black moveable arm and reassembled the device. It now moves the tape forward where it did not before,

Also, some goofy lady posted a youtube video about cleaning the device. She says her labelmaker did not come with the cleaning tool, but in her video, you can see the tool attached to the underside of the lid on her labelmaker. Clearly she is clueless. Don’t watch that video. You can use the tool to clean between the roller and the label guide if the label maker is printing too light or not at all.

Fue útil esta respuesta?

Hi!

I would suggest that you try a different cartridge. Most likely the ribbon is broken inside the cartridge. You can test this by turning the spool in the direction of the arrow with the cartridge out of the machine. These cartridges are designed to be removed/swapped in mid cartridge, so you won't be messing anything up by pulling it out.

Cheers!

If you found that information to be useful, please Up Vote or Accept Answer

Fue útil esta respuesta?

I've already tried with a new cartridge so I don't think this to be the problem :/

Hi!

Would you be able to post a pic of the compartment?

Cheers,

Joshua

There you have : http://tinyurl.com/jzshpsk

I tried to view the image, but it says that I do not have permission to view it.

It just downloads when you click this URL.

Great post Congratulations! in Brazil I use ribbons from Adegraf, it has taken care of well! Ribbon Elgin

Fue útil esta respuesta?

Reading Jepthas answer I moved the compartment door slowly to closed position and saw, that the print head did not move. Stuck my finger behind the printing head pressing it a few times against the black rubber roller. Did the trick. After reinstalling the cartridge, it printed OK again.

Fue útil esta respuesta?

While this is a fairly old question, I am hopeful my answer may help others in the future - My label printer was working fine, I ran out of tape and put a new one in, but the new one wouldn’t print anything. It looked as if everything was working, but the tape wasn’t moving. I tried another role of tape - one that I knew had worked previously, but it was the same issue there, so I knew it wasn’t a faulty tape cartridge. I read online that sometimes these label printers can power on but not have enough juice in the batteries to push the printer tape through. I changed the label printer for a couple of hours and everything is now working.

Fue útil esta respuesta?

Regarding ribbon not moving during printing on a Dymo LetraTag LT-100T with a variety of 12mm Dymo LetraTag label cartiges.

In my case when the cartridge door was closing it looked like it was clamping down the tape between the head and the motorised rubber roller.

In my case I had not used the printer for a couple of years at least. I think this caused one or more of the following of the following:

I think this has the effect of reducing the traction the rubber had on the tape. (If you try to pull the tape of out the cartridge by hand it's worth noticing that it requires substantial force. Therefore good traction is required. )

It looks like I used a combination of tactics to fix this.

In my case the lever operated b

In the first instance I thought the head clamp was not exerting enough pressure. I tried to address this by manual pressure on the lever operated by the cartridge door knob. This did not help. The tape was slipping on the rubber roller. I then decided to clean the rubber. For this I put vodka on the provo ides mini sponge brush. I typed single letter on the device and hit print while the sponge was pressed against the rubber roller. This probably cleaned off the dust but it left behind fragments of the sponge vrush on it. I then applied basic clear sticky tape (sellotape type) to pick up any remaining fragments from the rubber roller. Finally a put the cartridge in, closed the door and printed a single letter. Opened the cartridge door, pulled the tape out 5mm. Closed the door. Then repeated the printing and pulling a few times.

I applied one additional hack in order to increase the pressure from the print head on the roller. I applied 5 to 15 strips of sellotape to the cartridge door knob where it applies force on the printhead lever. I would exercise caution with this step. Don't add too many in one go. Also close the cartridge door slowly and pay attention to the door hinges and the pressure required to click it shut. Remove layers if too much pressure is required or it looks like the hinges are popping off.

If you asked me what made the biggest difference, I would say it was to very patiently clean the rubber roller of all dust particles. In this I think the alcochol spirit helped as a cleaning agent.

Repeat at your own risk.

Good luck.

Fue útil esta respuesta?

pierreavignon and Lindsay Heyes. You two were spot on! Ribbon was neatly wrapped around the roller. The roller (on mine) should have been solid white, but the ribbon was so neatly wrapped, it looked deceiving. I carefully cut it off and cleaned it up and feeder was perfect again. Many thanks!

Fue útil esta respuesta?

YES! In my case, the tape got wrapped around the rubber roller and I had to remove with tweezers, but wouldn't have noticed if it weren't for the other responses.

Fue útil esta respuesta?

Sometimes the issue is caused by the cutter in the DYMO Labelmanager. Ensure you clean it well as it can get very sticky from the glue on the labels. At some point the label gets "stuck" to the cutter every time you start printing. Cleaning the cutter (back-side and front-side) with e.g. alcohol will remove the residual glue.

Fue útil esta respuesta?

Label Manager 280

The ribbon compartment cover is linked with spring to a contraption of two plastic levers. These levers are pushing the thermal head toward to the roller when the back cover is closing.

In my case the spring was detached from the plastic lever because this plastic quality was poor and the little hole was cut.

I was forced to create a new hole and line the spring to this one. Oh dear, this was quite difficult task.

I still have some print quality issues since I nee to adjust the spring to push harder the head into the roller.

Fue útil esta respuesta?

I have just experienced this problem myself.

I decided to try new batteries and they worked....Putting the old ones back in and it still worked....

Conclusion:

Removing Batteries would have been like 'Turning it off and on again'

The red on/off button is known as a 'Soft' power button which its circuitry needs to have power to operate so the unit isn't fully off when you turn it off...so removing batteries really does turn it off and basically 'Re-Boots' the unit like you would re-boot a pc if some software hangs the pc....

Fue útil esta respuesta?

Ultimas 24 horas: 28

Ultimos 7 días: 216

Ultimos 30 días: 900

Todo El Tiempo: 76,681

21 comentarios

changed cartridge and still doer not put out tape !

- de broermansrdl

Another possible problem to look for: when you close the door to the tape-holding compartment, look to see whether the writing head moves to pinch the ink ribbon and printed tape together. If it does not, the hinged wire and spring component with a hook at the end may no longer be attached to a plastic eyelet that normally allows this pinching action to occur. This can be challenging to fix, which is a shame, because a tiny plastic part brings down the whole operation. I have not managed yet to fix this on my own label maker.

- de Jeptha Davenport

I fixed it! So, as above, the tiny arm was not pinching the tape onto the white roller, so it was not able to print anything on the tape. Soo... I kept the door open, got the LabelMaker all ready to print, all I'd have to do is press the Print button. Then I'd stick a paperclip behind the little arm to force it to pinch the tape against the white roller, then I'd hit Print, while I was doing this, AND IT WOULD WORK. The problem is, sometimes I wouldn't press hard enough on the arm, and it would have long streaks of white in the print area. But it was perfect if I pressed on the arm hard enough, so that it was pinchign the tape tightly. I emailed Dymo to see if there was a way I could fix this. I can't do this everytime.

- de Jessica Wilson

Thanks Jessica! That’s the same problem I had. Wish there was way to fix it

- de todd_j

Had the same problem. Here is how I fixed it: There is a spring connected from the door to a level arm inside the dymo. The lever arm has a small hole where the spring is hooked in. This hole broke out for me. I just drilled a new hole in the lever arm a little closer to the axis and now it works again! Getting the spring in the new hole is a little tricky but with some practice one can catch the spring with the hole and then put the axis in afterwards.

- de Albert Einstein

Mostrar 16 comentarios más