Qué necesitas

-

-

Use Provided M3 Bolts to attach wheel mounting plate to the wheel hub.

-

-

-

If using 63xx motors use a masking tape to prevent nuts from falling from motor mounting plate.

-

Attach the plate and use 4 x M3 bolts to attach motor plate to the motors

-

-

-

-

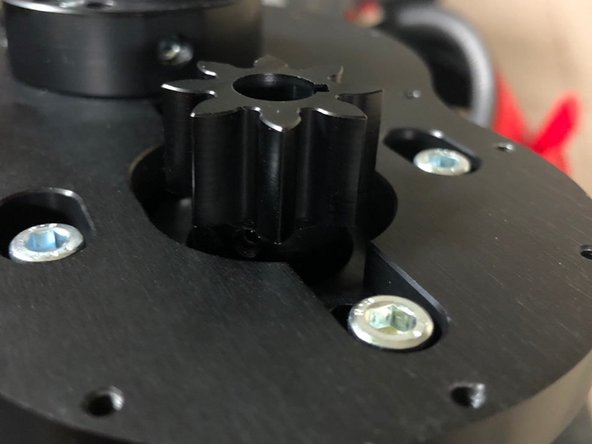

Use Loctite 648 to secure grub screws inside the motor gear to prevent loosening from vibrations.

-

-

-

Use provided 4 x M3 bolts to attach motor (with motor mount adapter if use)

-

-

-

Use 5 x M4 bolts to attach wheel gear to the wheel hub for gear meshing.

-

-

-

Attach wheel to the hanger and lower down motor to prepare gear meshing.

-

If wheel gear one side is pulled in or further than other sides check wheel hub bolts probably one bolt is more tighten than others or otherwise

-

If wheel gear is more inside than motor gear use washers provided to pull wheel gear away from baseplate

-

Loosen up motor bolts so that motor gear would press wheel gear.

-

Use sheet of paper to drive it through wheel gear and motor gear. Spin wheel to push paper through the gears

-

After meshing is good tighten motor bolts

-

-

-

Tighten motor bolts to secure motor in correct position

-

Remove wheel from wheel gear

-

Use grease to lubricate gears.

-

-

-

Put the plastic lid with stainless steel plate on top of it and tighten all M2.5 bolts

-

Lubricate V-Ring using grease on ID and on the flap. Mount the V-Ring on top of wheel gear

-

-

-

Do a test spin on the bench to make sure everything is fine and sounds okay

-

On the first test ride start by slowly accelerating and slowly braking to make sure everything is working fine.

-

If there is some minor vibration happening at specific RPM it can be some misbalance in wheel/gears which should disappear after gears sit down in their place.

-

To disassembly gear drive, follow these instructions in reverse order.

To disassembly gear drive, follow these instructions in reverse order.